Choosing between electric and manual tongs significantly impacts drilling efficiency and safety. Manual tongs offer simplicity, durability, and precise control during gripping and clamping of drill pipes. However, electric tongs enhance power delivery and reduce manual handling fatigue, leading to faster operation cycles. For operators balancing cost control, product quality, and timely delivery, understanding these tools' core strengths and suitable scenarios is essential.

Understanding Manual Tongs: Traditional Strength in Drilling Operations

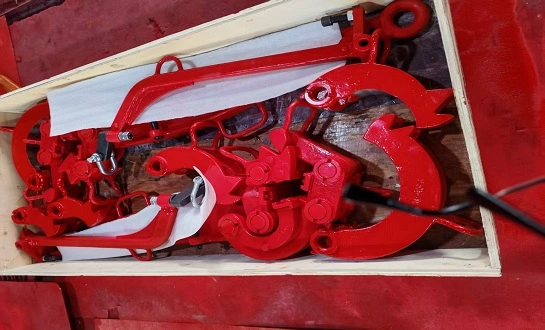

Manual tongs have served the industry for decades, excelling in providing a mechanical advantage through leverage and precision. They are primarily designed for gripping and clamping drill pipes during metalwork and forging activities. Their ergonomic construction and non-slip surfaces ensure safety and control during heavy-duty applications even under heat-resistant conditions.

Three core features distinguish manual tongs:

- Adjustability to accommodate various pipe sizes ensuring versatile usage.

- Durability and rugged craftsmanship suitable for industrial workshops and construction environments.

- Mechanical advantage facilitating controlled manual handling without overexertion.

If you need durable, straightforward equipment with precise control and minimal maintenance, manual tongs remain a reliable choice. Their simplicity reduces the risk of malfunctions and eases onsite repair, contributing to stable and timely delivery in the manufacturing supply chain.

Electric Tongs: Power and Automation in Drilling Applications

Electric tongs automate much of the physical effort required in pipe handling, utilizing powered drives to secure pipes efficiently. Their main advantage lies in reducing operator fatigue and improving throughput on rigs with high-volume drilling cycles.

Three main advantages of electric tongs according to industry test data:

- Increase in operational speed by up to 30% compared to manual methods (Source: Drilling Rig Efficiency Report, 2023).

- Consistent torque application resulting in uniform pipe connections and less wear (Industry Torque Analysis, 2022).

- Reduction of manual strain injuries by 40% demonstrated in ergonomic studies (Oilfield Safety Journal, 2021).

If your operation demands faster cycle times and enhanced safety through reduced manual handling, electric tongs will serve better. However, they require higher initial investment and maintenance infrastructure.

Pros and Cons of Manual Tongs vs. Electric Tongs: A Comparative Overview

| Feature | Manual Tongs | Electric Tongs |

|---|---|---|

| Initial Cost | Lower; cost-effective for budget-conscious buyers. | Higher; requires investment in power and control systems. |

| Maintenance | Simple; fewer components, easier repairs onsite. | Complex; demands skilled technicians and regular servicing. |

| Operational Speed | Moderate; dependent on manual strength and skill. | High; powered drive increases efficiency significantly. |

| Durability | Highly durable; designed for rugged, heat-resistant conditions. | Durable but sensitive; electronic parts vulnerable to harsh environments. |

| Precision on Torque | Good; operator-dependent but allows fine control. | Excellent; consistent torque reduces pipe wear. |

| User Fatigue | Higher; demands physical effort from operators. | Lower; powered assistance lessens manual strain. |

Applicable Scenarios of Manual Tongs and Electric Tongs in Drilling Projects

Manual tongs are best suited for projects requiring robust, cost-efficient hand tools and situations where electrical infrastructure might be limited — such as remote or smaller scale operations. Their heat-resistant and mechanical advantage makes them ideal for various metalwork and forging challenges on-site.

Electric tongs find their place in large-scale drilling operations needing rapid pipe handling with an emphasis on worker safety and uniformity in pipe connections. The ergonomic benefits and workshop automation support heavier workloads efficiently.

If your site lacks stable power supply or values low upfront investment, manual tongs are preferable. For high throughput and automation-friendly scenarios, electric tongs provide clear advantages.

Highlighting WELONG's Manual Tongs Advantages

WELONG's manual tongs stand out in the oilfield equipment industry due to decades of craftsmanship and stringent quality controls. Their lineup includes the Type SDD, DB, SB, B, and well service manual tongs — all built for heavy-duty, precision gripping, and versatile adjustability.

Key advantages include:

- Exceptional Durability: Manufactured using premium, heat-resistant alloys ensuring long service life even under demanding conditions.

- Strict Quality Control: ISO 9001:2015 and API 7-1 certified quality management guarantees dependable performance and product consistency.

- Ergonomic Design: Optimized grip and non-slip surfaces reduce operator strain and enhance safety during manual handling.

- Precise Mechanical Advantage: Expertly engineered leverage systems allow smooth, powerful clamping with high precision.

- On-Time Delivery: Comprehensive supply chain support ensures products arrive reliably at customer warehouses using sea, air, or railway.

- Comprehensive Inspection Services: Includes in-process, final, and third-party inspections with partners like SGS and DNV, ensuring product quality before dispatch.

If your procurement criteria emphasize stable product quality and reliable after-sales service alongside cost control, WELONG's manual tongs provide an unbeatable balance.

Making an Informed Choice: Manual Tongs vs. Electric Tongs

Buyers must consider project scale, workforce capabilities, and cost frameworks. Manual tongs offer rugged simplicity and enable stable, low-cost operations with precision. Electric tongs bring automation and speed, ideal for industrial environments focusing on throughput.

Five evaluative factors to consider:

- Budget Constraints and Total Cost of Ownership: Manual tongs are generally more affordable upfront, but electric tongs, while initially more expensive, can offer long-term cost savings through improved efficiency and reduced labor costs.

- Operational Environment and Power Accessibility: Electric tongs require a consistent power source, making them more suitable for large-scale operations with reliable power access. Manual tongs, however, are better for remote or power-limited environments where portability is crucial.

- Safety and Ergonomic Requirements: Electric tongs often have built-in safety features and ergonomic designs that reduce the physical strain on workers, making them ideal for high-volume, repetitive tasks. Manual tongs, while simpler, can require more physical effort and may present higher safety risks in prolonged use.

- Maintenance Capability Onsite: Manual tongs are easier and cheaper to maintain, with fewer components to repair. In contrast, electric tongs may require specialized knowledge for repairs and maintenance, which could add operational downtime.

- Inspection and Quality Assurance Needs: Electric tongs often come equipped with automated monitoring systems that provide real-time feedback on performance, ensuring high-quality results. Manual tongs rely more on the operator’s skill and experience to achieve consistent quality.

Careful matching of these factors ensures selection of the optimal tong type that enhances productivity while aligning with procurement and engineering expectations.

Conclusion

Both manual and electric tongs provide vital functions in drilling operations, with distinct advantages tailored to specific operational demands. Manual tongs, especially those from WELONG, excel in reliability, durability, and cost efficiency, supported by rigorous quality controls and customer-focused service. As a trusted Manual Tongs supplier, WELONG ensures that its products meet the highest industry standards, offering a dependable solution for cost-effective operations. Electric tongs boost speed and safety but require greater investment and maintenance resources. Considering your project scale, power availability, and operator needs will guide you to the best fit, fostering safer, more efficient drilling outcomes.

Where to Buy Manual Tongs

Looking for high-quality manual tongs backed by over two decades of expertise? WELONG offers a comprehensive range tailored for oilfield drilling operations. Our strict quality management, versatile transportation options, and dependable after-sales service ensure your procurement needs are met efficiently. Contact us at oiltools15@welongpost.com to inquire about "Manual Tongs" and discover how we can support your drilling projects.

References

- Drilling Rig Efficiency Report, 2023, International Petroleum Institute

- Industry Torque Analysis, 2022, Mechanical Engineers Association

- Oilfield Safety Journal, Ergonomic Studies on Tool Usage, 2021

- ISO 9001:2015 Certification Documentation, WELONG Quality Control Division

- API 7-1 Standards for Drill Stem Elements, American Petroleum Institute, 2023

- Third-Party Inspection Reports with SGS and DNV, 2022–2024