What is a super fishing jar and how does it work? In the oil and gas drilling industry, a super fishing jar represents one of the most critical downhole tools for recovering stuck pipe and equipment during drilling operations. This specialized piece of fishing equipment delivers controlled jarring action to dislodge stuck assemblies, saving operators thousands of dollars in potential sidetracking costs. Super fishing jars work by storing mechanical energy through compression or tension, then releasing it in a controlled impact to free stuck downhole components. Understanding how these tools function can mean the difference between a successful recovery operation and an expensive drilling setback.

What is a Super Fishing Jar?

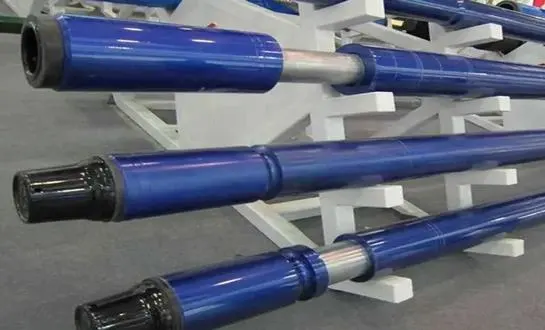

A super fishing jar stands as an essential downhole tool specifically engineered for fishing operations in oil and gas wells. These robust devices generate powerful jarring forces to free stuck drill strings, casing, tubing, or other downhole equipment that becomes lodged during drilling or completion operations. The "super" designation indicates enhanced capabilities compared to standard jars, including greater impact force, improved reliability, and extended operational life.

Operating Principle and Mechanism

Super fishing jars operate on mechanical principles that store and release energy. The tool consists of an outer mandrel and inner sleeve assembly. When tension is applied, the fishing jar accumulates energy until a trigger point releases it instantaneously, creating a powerful impact downhole.

Design Configurations and Applications

Super fishing jars are available in multiple configurations to suit well conditions, using durable metallurgy and precise impact delivery to free stuck pipe, minimizing operational downtime and reducing financial losses for drilling contractors.

The Critical Problem Super Fishing Jars Solve

Stuck pipe incidents cause significant financial losses, accounting for 25% of drilling non-productive time. Unsuccessful recovery often leads to costly sidetracking operations and permanent equipment loss. These failures also waste reserves and increase the environmental footprint of drilling projects.

limitations of traditional recovery

Traditional fishing methods, including standard fishing jars, often fail in severe sticking due to insufficient impact force. They struggle against high holding forces from differential sticking or wellbore instability. This inadequacy elevates the risk of expensive well interventions.

advantages of advanced technology

Super fishing jars provide substantially higher impact forces and reliable triggering mechanisms. They perform effectively in complex directional and extended-reach wells. This technology overcomes the limitations of standard equipment in challenging downhole conditions.

Core Features and Functionality Deep Dive

The mechanical design of super fishing jars incorporates several key features that distinguish them from conventional fishing tools.

Key Component Configuration

The primary component is a telescopic assembly with an outer housing and inner mandrel, allowing controlled movement. The mandrel travels within the housing to a trigger point, releasing accumulated energy instantly for impact.

Energy Storage Mechanisms

Energy storage varies among super fishing jar designs. Compression jars store energy by compressing springs or hydraulic fluids, while tension jars accumulate it through upward pulling forces. Combination jars offer both capabilities for different fishing scenarios.

Triggering and Impact Systems

Triggering systems include mechanical force thresholds or hydraulic delays for controlled activation. Upon release, the internal components accelerate, delivering a powerful shock wave through the drill string to the stuck point via the Fishing Jar.

Advanced Technology and Engineering Principles

Engineering Design and Analysis

Finite element analysis optimizes the Fishing Jar design by predicting stress and refining geometries for maximum impact and structural integrity under extreme downhole conditions.

Advanced Materials and Protection

Specialized alloys and heat treatments provide strength and corrosion resistance, while coatings further enhance the Fishing Jar's durability against drilling fluids and mechanical wear.

Hydraulic Systems and Control

Precision hydraulic components, including valves and orifices, regulate fluid flow to ensure consistent triggering and reliable energy release across varying wellbore temperatures and pressures.

Key Advantages and Selling Points

Enhanced Impact and Efficiency

Super Fishing Jars deliver significantly higher impact forces, crucial for severely stuck equipment. This improves recovery success while reducing jarring cycles, cutting rig time and overall fishing costs.

Superior Reliability and Performance

Advanced manufacturing ensures consistent performance across multiple cycles. This reliability is critical in fishing operations, where jar failure could lead to costly sidetracking and lost equipment.

Versatility and Adaptability

Different trigger mechanisms allow customization for specific well conditions. This reduces the need for specialized tools and simplifies fishing string design with a single, adaptable super fishing jar.

Cost-Effectiveness and Value

Higher initial costs are offset by faster operations and improved success rates. The reduced risk of failed attempts and sidetracking yields savings that far exceed the tool investment.

Extended Operational Life

Robust construction and premium materials enable withstanding multiple operations without performance loss. This longevity reduces replacement frequency and inventory costs.

Enhanced Safety Features

Controlled energy release prevents excessive shock loads, protecting surface equipment and rig crews. Predictable triggering allows for safe and effective operation planning.

Potential Limitations and Important Considerations

Super fishing jars require careful selection and application to achieve optimal results. The enhanced capabilities of these tools can create challenges if not properly matched to specific fishing scenarios. Excessive jarring forces may damage stuck equipment or surrounding wellbore components, potentially complicating recovery efforts. Proper engineering analysis and experienced fishing supervision help mitigate these risks.

Economic justification

Cost considerations may influence the decision to use super fishing jars versus alternative fishing methods. The higher initial investment for a Fishing Jar requires justification based on expected challenges. Operators must weigh this cost against potential savings from improved success rates.

Personnel training

Training requirements ensure safe and effective use of super fishing jars. Their enhanced capabilities demand proper training for all fishing personnel. Inadequate training can lead to improper application, reduced effectiveness, or safety hazards.

Tool maintenance

Maintenance requirements ensure continued reliability throughout the tool's service life. A super Fishing Jar requires periodic inspection, testing, and refurbishment. This maintenance maximizes tool life and reliability while minimizing unexpected failures.

Wellbore conditions may limit the effectiveness of super fishing jars in certain situations. Severe washouts, unstable formations, or extreme dogleg severity can affect jar performance. Proper pre-fishing analysis helps identify potential limitations and develop appropriate mitigation strategies.

Competitive Analysis and Market Position

Traditional Fishing Jar Limitations

Traditional hydraulic and mechanical Fishing Jar tools offer cost-effective solutions but lack sufficient impact force and adjustability for severe stuck pipe incidents, limiting their effectiveness in complex modern drilling operations.

Emergence of Advanced Accelerators

Advanced accelerator systems introduce new energy delivery methods, yet their complexity increases training and maintenance costs, making them unsuitable for all fishing applications despite potential effectiveness.

Superiority of Super Fishing Jars

Super fishing jars provide superior impact force, reliability, and versatility through advanced materials and optimized designs, excelling in challenging scenarios where conventional tools fail and aligning with demanding market trends.

Target Applications and Ideal Use Cases

Primary Market: Drilling Contractors

Drilling contractors form the primary market for the Fishing Jar, especially in challenging environments where stuck pipe incidents are frequent. They rely on its superior capability to minimize non-productive time and justify the investment through enhanced performance in complex wells.

High-Value Operations: Oil & Gas Operators

Oil and gas operators benefit from the super fishing jar in high-value wells, such as deepwater or extended-reach projects, where fishing success critically impacts economics. Its superior performance protects significant investments by improving recovery rates in essential operations.

Integrated Solutions: Equipment Manufacturers

Drilling equipment manufacturers integrate the super fishing jar into comprehensive fishing tool packages for customers. This premium solution enhances their product portfolios and provides a competitive edge in addressing the most challenging stuck pipe scenarios.

Specialized Services: Fishing Companies

Fishing service companies utilize the super fishing jar as a specialized tool for complex recovery operations where conventional methods have failed. It provides the enhanced capability needed to successfully tackle these difficult situations.

Remote Operations: International Drilling

International drilling operations benefit significantly due to high costs and logistical challenges in remote locations. The Fishing Jar helps minimize the risk of expensive sidetracking or equipment replacement by improving success rates where mobilization is costly.

Niche Applications: Geothermal Drilling

Geothermal and specialized drilling applications face extreme temperatures and corrosive fluids. The robust super fishing jar provides reliable performance under these demanding conditions, offering an effective solution for challenging formations.

Conclusion

Super fishing jars represent essential tools for modern drilling operations facing increasingly complex stuck pipe challenges. Their advanced engineering, superior materials, and enhanced capabilities provide the reliability and performance needed to protect valuable drilling investments. As drilling operations push into deeper, more challenging environments, the importance of effective fishing solutions will continue to grow. The technology behind super fishing jars continues evolving, with ongoing improvements in materials, design optimization, and manufacturing processes promising even better performance in future generations. For drilling professionals seeking to minimize fishing-related risks and costs, investing in premium super fishing jar technology delivers measurable returns through improved success rates and reduced non-productive time.

Frequently Asked Questions

Q1: How do super fishing jars differ from standard mechanical jars in terms of impact force?

A: Super fishing jars typically deliver 2-3 times more impact force than standard mechanical jars through advanced energy storage systems and optimized internal designs. This enhanced capability proves crucial for freeing severely stuck equipment that conventional jars cannot dislodge.

Q2: What factors should be considered when selecting a super fishing jar for specific well conditions?

A: Key factors include wellbore geometry, mud weight, temperature, type of stuck equipment, and severity of the stuck condition. The jar's trigger mechanism, energy storage capacity, and size compatibility with the fishing string also influence selection decisions.

Q3: How often should super fishing jars undergo maintenance and inspection?

A: Industry best practices recommend inspection after every 10-15 jarring cycles or following any fishing operation where unusual forces were encountered. Annual comprehensive inspections should include disassembly, component examination, and pressure testing to ensure continued reliability.

Partner with WELONG for Premium Super Fishing Jar Solutions

WELONG stands as your trusted fishing jar manufacturer, delivering superior quality downhole tools that meet the demanding requirements of modern drilling operations. Our extensive experience in oilfield products and customized solutions positions us uniquely to understand your specific fishing challenges and provide effective solutions. Since our founding in 2001, we have built a reputation for excellence in the international supply chain, focusing on empowering drilling operations with the finest equipment available.

Ready to enhance your fishing capabilities with premium super fishing jar technology? Our team of experienced professionals stands ready to discuss your specific requirements and recommend the optimal fishing solutions for your operations. Whether you're dealing with routine stuck pipe situations or complex fishing challenges, WELONG has the expertise and equipment to help you succeed. Contact us at oiltools15@welongpost.com to learn more about our comprehensive range of fishing tools and discover how our customized solutions can improve your drilling efficiency while controlling costs.