How 3D Printing Enhances Hole Openers?

The advent of 3D printing technology has revolutionized the manufacturing process of hole openers, bringing unprecedented advantages to the oil and gas industry. This innovative approach allows for the creation of complex geometries and internal structures that were previously impossible or prohibitively expensive to produce using traditional manufacturing methods.

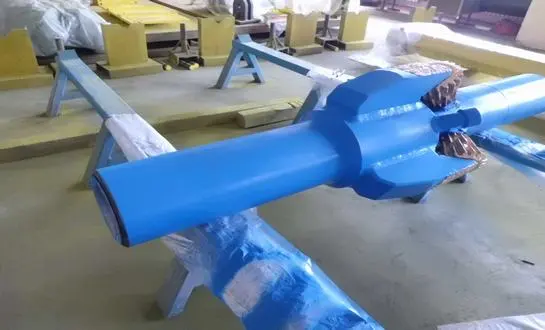

Precision and Complexity

3D printing enables the production of hole openers with intricate designs and precise specifications. This level of detail is crucial for optimizing fluid flow dynamics and cutter placement, resulting in more efficient drilling operations. The ability to fine-tune the tool's structure at a microscopic level leads to improved performance in various geological formations.

Material Innovation

With 3D printing, manufacturers can experiment with a wide range of materials, including advanced alloys and composites. This flexibility allows for the development of hole openers that are lighter, stronger, and more resistant to wear and corrosion. For instance, the use of AISI 4145H MOD or AISI 4330V alloys in 3D-printed hole openers can significantly enhance their durability and performance in challenging drilling environments.

Customization for Specific Formations

One of the most significant advantages of 3D-printed hole openers is the ability to quickly customize tools for specific geological formations. Whether dealing with hard, medium, or soft formations, engineers can rapidly design and produce hole openers tailored to the unique challenges of each drilling site. This level of customization was previously time-consuming and costly with traditional manufacturing methods.

Cost-Efficiency vs. Traditional Manufacturing: A Comparative Analysis

The introduction of 3D printing technology in the manufacturing of hole openers has sparked a significant shift in the cost dynamics of tool production. To fully appreciate the impact of this innovation, it's essential to conduct a thorough comparative analysis between 3D printing and traditional manufacturing methods.

Initial Investment and Setup Costs

Traditional manufacturing of hole openers typically requires substantial initial investments in machinery, molds, and tooling. These upfront costs can be prohibitive, especially for smaller companies or specialized projects. In contrast, 3D printing technology, while requiring an initial investment in printers and software, offers more flexibility and lower setup costs for producing a wide range of hole opener designs.

Production Speed and Turnaround Time

One of the most significant advantages of 3D printing is the rapid prototyping and production capability. While traditional manufacturing methods may take weeks or even months to produce a new hole opener design, 3D printing can accomplish the same task in a matter of days. This quick turnaround time is particularly valuable in the fast-paced oil and gas industry, where reducing downtime is crucial.

Material Efficiency and Waste Reduction

Traditional subtractive manufacturing methods often result in significant material waste, as excess material is cut away to achieve the desired shape. 3D printing, being an additive manufacturing process, uses only the material necessary for the final product. This efficiency not only reduces waste but also lowers material costs, especially when working with expensive alloys commonly used in hole opener production.

Customization and Small Batch Production

3D printing excels in scenarios requiring customized or small batch production of hole openers. Traditional manufacturing becomes cost-prohibitive for small runs due to the high setup costs. In contrast, 3D printing allows for economical production of customized hole openers tailored to specific drilling conditions, without the need for expensive molds or tooling changes.

Customization Potential: Tailoring Hole Openers for Specific Formations

The ability to customize hole openers for specific geological formations represents one of the most promising aspects of 3D printing technology in the oil and gas industry. This level of tailored design was previously challenging and often economically unfeasible with traditional manufacturing methods.

Adapting to Diverse Geological Conditions

Different drilling locations present unique challenges due to varying rock compositions and formations. 3D printing allows engineers to design hole openers that are optimized for specific geological conditions. For instance, a hole opener designed for hard formations can be quickly modified and printed to suit softer or medium formations, ensuring optimal performance across diverse drilling environments.

Optimizing Cutter Placement and Design

With 3D printing, the placement and design of cutters on hole openers can be precisely controlled and easily modified. This capability allows for the creation of hole openers with optimized cutter configurations that enhance cutting efficiency and reduce wear. Engineers can experiment with various cutter layouts and quickly produce prototypes for testing, accelerating the development of more effective hole opener designs.

Enhancing Fluid Dynamics

The internal geometry of hole openers plays a crucial role in fluid dynamics during drilling operations. 3D printing enables the creation of complex internal channels and structures that optimize fluid flow, improving debris removal and cooling efficiency. These intricate designs, difficult to achieve with traditional manufacturing, can significantly enhance the overall performance and lifespan of hole openers.

Rapid Iteration and Field Testing

The speed and flexibility of 3D printing allow for rapid iteration in hole opener design. Engineers can quickly produce multiple variations of a design for field testing, gathering real-world performance data to inform further improvements. This iterative process, conducted in a fraction of the time required by traditional methods, accelerates innovation and leads to more effective hole opener designs tailored to specific drilling challenges.

Conclusion

The integration of 3D printing technology in the manufacturing of hole openers represents a significant leap forward for the oil and gas industry. As we've explored, this innovative approach offers numerous advantages over traditional manufacturing methods, including enhanced customization, improved cost-efficiency, and the ability to rapidly iterate designs for optimal performance in diverse geological formations.

The potential for 3D-printed hole openers to revolutionize drilling operations is clear. By enabling the production of tools tailored to specific drilling conditions, this technology promises to improve efficiency, reduce downtime, and ultimately lower the costs associated with oil and gas exploration and production.

As the technology continues to mature and become more widely adopted, we can expect to see further innovations in hole opener design and performance. The future of drilling operations looks bright, with 3D-printed hole openers leading the way towards more efficient, cost-effective, and environmentally friendly practices in the oil and gas industry.

For those interested in staying at the forefront of this technological revolution, partnering with forward-thinking manufacturers is crucial. Welong, with its commitment to innovation and quality, stands ready to meet the evolving needs of the industry with cutting-edge 3D-printed hole opener solutions. To learn more about our advanced hole opener products and how they can benefit your drilling operations, please contact us at oiltools15@welongpost.com.

FAQ

1. What are the main advantages of 3D-printed hole openers over traditionally manufactured ones?

3D-printed hole openers offer several advantages, including enhanced customization for specific geological formations, reduced manufacturing time, improved material efficiency, and the ability to create complex geometries that optimize performance. They also allow for rapid prototyping and iteration, leading to more effective designs.

2. How does 3D printing technology impact the cost of producing hole openers?

While the initial investment in 3D printing technology can be significant, it often leads to reduced overall production costs. This is due to decreased material waste, lower setup costs for new designs, and the ability to produce small batches or custom tools economically. The technology also enables faster production times, potentially reducing operational costs associated with tool procurement.

3. Can 3D-printed hole openers match the durability and performance of traditionally manufactured ones?

Yes, 3D-printed hole openers can match and often exceed the durability and performance of traditionally manufactured ones. Advanced materials and precise manufacturing techniques allow for the creation of tools with optimized structures and compositions. Additionally, the ability to rapidly iterate and improve designs based on field performance data contributes to the development of highly effective and durable hole openers.