How successfully and safely oil and gas drilling operations perform depends on wellbore cleanliness. Contaminated casing walls obstruct flow, destroy equipment, and generate expensive downtime that decreases project profitability. Drilling contractors realize that effective casing scraper tools improve well performance and equipment life. Modern wellbore cleaning needs gear designed for specific downhole issues. Cement, drilling mud, scale, and perforation burrs accumulate during completion. These toxins impede productivity and make future treatments riskier. Effective cleaning solutions remove various dirt while preserving the casing.

Know wellbore conditions and operating objectives to pick the finest cleaning equipment. Experienced engineers consider casing needs, contaminants, project timetable, and budget. Quality manufacturers provide entire cleaning product lines for global drilling markets.

Why Pay Attention to High-End Wellbore Cleaning Tools?

Buying wellbore cleaning equipment is a big investment that will pay off in the long run and make operations run more smoothly. Cleaning tools that aren't up to par don't get rid of all the debris, which causes production losses and equipment damage that cost more than the initial cost savings. Professional drilling operations put a high value on cleaning solutions that they know will work, even when conditions deep underground are tough.

Quality pipe scraper tools lower operational risks by being designed to handle a wide range of contamination situations. Premium manufacturers use strict testing methods and material requirements to make sure that their equipment works well during important cleaning tasks. This method cuts down on equipment breakdowns and project delays that can affect drilling schedules and how well the budget works.

When you buy professional-grade cleaning equipment, it pays for itself in less time and money through higher well productivity and lower maintenance costs. As long as the well is in use, clean casing walls will improve flow characteristics and equipment performance. Drilling contractors know that thorough cleaning programs protect big investments in infrastructure and make the whole project more profitable.

Tips for Choosing the Best Cleaning Products

Why should you buy wellbore cleaning equipment? Because it works, how much it costs, and how well it does its job. A lot of different factors are used by experts in the field to find the best ways to clean while staying within budget and on time.

When making a casing scraper choice, the most important things to think about are how well it removes debris, how deep it can go, and how well it can work with different casing specifications. It's important for the equipment to show that it can get rid of the right kinds of contamination and still work properly at the temperatures and pressures that will be found underground.

Some economic factors are how much the equipment costs, how well it works, and how much upkeep it will need over time. The total cost analysis looks at how much the item costs, how much it costs to use, how often it needs to be maintained, and how long it is supposed to last. Good manufacturers have clear prices and a lot of support services that help you figure out how much something will cost.

It's important to know about operational factors like the availability of equipment, delivery times, technical support, and training needs. Suppliers you can trust make sure they have enough stock on hand and can deliver quickly if you need something for a project right away. Full technical support helps with problems to make sure that equipment is used correctly and that things run smoothly.

What Are the Best Bow Spring Scraper Systems?

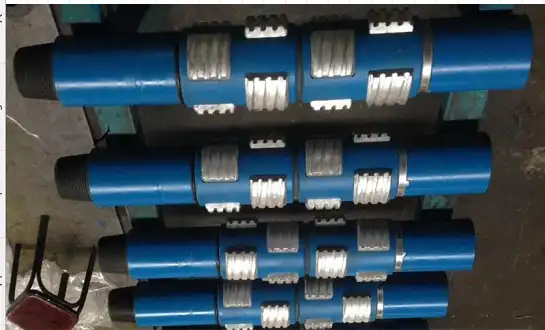

When there are a lot of different wellbore conditions, bow spring scraper systems clean the casing the best. When these tools are used, the cutting edges on the steel arms fit against the walls of the case. The arms can be bent. The design with the spring makes sure that the contact pressure stays the same, even if the diameter or casing changes a little.

Here are a few important benefits:

- Because it is flexible, you can use the same tool with different-sized cases.

- Stretchy arms can easily move around small changes and casing joints without getting stuck.

- The costs of running a machine over time are lower if the cutting elements can be changed.

- Tested to remove drilling mud, cement residue, and scale deposits.

- Standard drilling tools and methods for setting them up can be used.

- It doesn't need much upkeep. lessen the difficulty of operations.

The installation process is still very easy; all that is needed is standard drilling equipment and well-known steps for setting it up. Features that make handling easier and need less training are liked by operators because they make operations easier. When a company makes good casing scraper tools, they make it easy to use them in the best way for each project by giving clear instructions and technical help.

Solutions for Rigid Blade Scrapers

Rigid blade scrapers clean aggressively in situations with a lot of contamination that need the most force to remove debris. These tools have cutting edges that stay in place while they're being used, making sure that they stay in contact with the walls of the casing throughout the cleaning process.

Some operational benefits are:

- Stronger cutting power gets rid of tough cement and scale deposits.

- Precision positioning of the blades ensures even cleaning.

- Strong construction can handle rough materials and high pressure.

- Different blade configurations deal with different kinds of contamination.

- Minimal deflection keeps cleaning working well in tough situations.

- Longer operational life cuts down on replacement costs and frequency.

Some things to think about before deployment are evaluating the condition of the casing and looking at the contamination to find the best cleaning parameters. Expert operators look at the types of debris and how bad the contamination is to choose the right blade configurations and operating methods. The best way to clean something while minimizing equipment stress and operational risks is to choose the right tools.

Cleaning systems that use hydraulics

Hydraulic-activated cleaning systems let you control the cleaning force by changing the fluid pressure. This lets you get rid of debris precisely without putting too much stress on the casing. These high-tech tools have hydraulic systems that can extend and retract cleaning elements depending on the job and the conditions downhole.

Some advanced features are:

- Adjustable cleaning force makes it easier to get rid of debris.

- Controlled deployment lowers the risk of damage to the casing during operations.

- Remote activation lets you precisely control timing and location.

- Multiple cleaning cycles are the best way to get rid of contamination.

- Pressure monitoring systems give feedback on operations and keep an eye on safety.

- Human error and the work of operators are both cut down by automated sequences.

System integration features let them be added to full well intervention programs that work on multiple downhole goals at the same time. Modern control systems let other intervention tools work together and allow real-time optimization based on feedback from operations and conditions downhole.

Technical specifications stress dependability and accuracy by using tried-and-true hydraulic parts and strong mechanical designs. Good manufacturers use thorough testing methods to make sure their products work as expected in real-world situations. Designs that have been tested in the field show consistent performance in a wide range of operational environments and geographic regions.

Global Market Analysis and Regional Considerations

International drilling markets exhibit varying technical requirements and regulatory frameworks that influence equipment selection and operational procedures. Global suppliers must address diverse specifications while maintaining consistent quality standards across different geographic regions and operational environments.

Regional factors affecting equipment selection include local technical standards, environmental regulations, and logistical constraints. Offshore operations require specialized corrosion resistance and compact designs that accommodate platform limitations. Onshore applications may prioritize cost efficiency and rapid deployment capabilities over specialized environmental resistance.

Regulatory compliance varies significantly across international markets, requiring equipment certification and documentation that meets local standards. Professional manufacturers maintain comprehensive certification programs that address major international markets while providing necessary documentation and technical support for regulatory compliance.

Supply chain considerations include regional inventory management, technical support availability, and local service capabilities. Global suppliers establish regional distribution networks that ensure rapid equipment availability and comprehensive technical support. Local partnerships enhance service delivery and reduce logistical complexity for international operations.

Purchasing Recommendations and Strategic Considerations

Strategic equipment acquisition entails assessing operating needs, supplier capabilities, and long-term costs. Professional drilling companies maximize equipment performance while controlling budgets and operational risks via methodical procurement.

Supplier assessment should highlight production quality, technical support, and delivery dependability. Experienced manufacturers provide better operational security and support. Quality certifications and industry standards conformance demonstrate production professionalism and consumer satisfaction.

Lifecycle cost analysis is more accurate than initial purchase price comparisons for procurement. Maintenance, operating efficiency, equipment longevity, and replacement frequency affect total cost. Quality equipment has a longer lifespan and lower running expenses.

Training, documentation, troubleshooting, and replacement parts are technical support needs. Comprehensive support programs minimize operational risks and maximize equipment use throughout the service lifespan. Reliable suppliers have enough technical and regional support to meet client needs quickly.

Conclusion

Selecting optimal casing scraper equipment requires careful consideration of operational requirements, performance capabilities, and supplier reliability. Quality cleaning tools deliver measurable returns through improved well performance and reduced operational risks. Professional drilling operations benefit from comprehensive equipment evaluation that considers total lifecycle costs and long-term operational objectives. WELONG's proven manufacturing excellence and comprehensive support services provide reliable solutions for demanding wellbore cleaning applications across global markets.

Frequently Asked Questions

Q1: How do I determine the right casing scraper size for my specific wellbore requirements?

A: Proper sizing depends on your casing inner diameter, contamination type, and operational constraints. Measure casing specifications accurately and consult with experienced suppliers who can recommend appropriate tool configurations. WELONG's technical team provides sizing guidance based on specific wellbore conditions and cleaning objectives.

Q2: What maintenance procedures extend scraper tool lifespan and performance?

A: Regular inspection of cutting elements, proper cleaning after operations, and scheduled replacement of wear components optimize tool performance. Store equipment in controlled environments and follow manufacturer guidelines for maintenance intervals. Quality suppliers provide detailed maintenance procedures and spare parts availability.

Q3: Can casing scrapers handle multiple contamination types during single cleaning operations?

A: Modern scraper designs effectively address mixed contamination scenarios including cement, mud, scale, and debris combinations. Tool selection depends on dominant contamination types and cleaning priorities. Professional suppliers recommend optimal configurations based on specific wellbore conditions and operational requirements.

Partner with WELONG for Superior Casing Scraper Solutions

WELONG makes high-quality wellbore maintenance equipment with 20 years of experience and excellent customer service. Our strict quality control ensures dependable performance under difficult operating circumstances, while low price supports your budget. A leading casing scraper manufacturer, we provide sea, air, and train delivery with FOB, CIF, DDP, and DDU terms to meet your logistics needs. The reliable delivery dates of our skilled manufacturing teams assist your project timetables and operational planning. We provide in-process, final, and optional third-party inspection via SGS and DNV agreements. We are ISO 9001:2015 and API 7-1 certified, proving our dedication to quality and professionalism.

Ready to optimize your wellbore cleaning operations with premium equipment and professional support? Contact us at oiltools15@welongpost.com to discuss your specific requirements and discover how WELONG solutions enhance your drilling operations.

References

1. Smith, R.J., "Advanced Wellbore Cleaning Techniques for Enhanced Production," Journal of Petroleum Technology, Vol. 75, 2023, pp. 45-52.

2. Johnson, M.K. and Williams, A.P., "Casing Scraper Performance Analysis in Deepwater Operations," Offshore Drilling Engineering Quarterly, Issue 3, 2023, pp. 78-85.

3. Chen, L.H., "Comparative Study of Mechanical Cleaning Tools for Wellbore Maintenance," International Drilling Technology Review, Vol. 28, 2023, pp. 112-119.

4. Anderson, D.R., "Quality Control Standards for Downhole Cleaning Equipment Manufacturing," Oilfield Equipment Standards Manual, 2023 Edition, pp. 203-215.

5. Thompson, K.S., "Economic Analysis of Wellbore Cleaning Programs in Global Drilling Operations," Petroleum Economics Quarterly, Vol. 42, 2023, pp. 67-74.

6. Rodriguez, C.M., "Environmental Considerations in Modern Wellbore Cleaning Operations," Sustainable Drilling Practices Journal, Issue 2, 2023, pp. 34-41.