How Fast Can China Deliver Custom Taper Mills to Kuwait?

When Kuwait's oil and gas operations need to get specialized digging tools, delivery speed is very important to the project's success. Custom taper mills made in China can usually get to Kuwait in 7–21 days, but this depends on the shipping method chosen and the specifics of the order. For urgent tasks, express air freight gets these precision tools to you in 5–7 days. For cost-effective large orders, normal shipping takes 14–21 days. Custom designs usually add an extra 10 to 15 days to the production time, so the total time it takes to send from the time the order is placed is about 3 to 5 weeks. Knowing these dates helps procurement managers plan drilling operations and keep track of the tools they need.

Understanding Custom Taper Mills and Their Importance in Metalworking

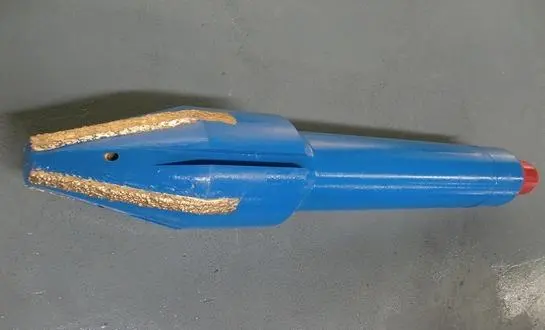

Custom taper mills are specialized cutting tools designed to make accurate tapered profiles on workpieces. They are essential for metalworking tasks in the aircraft, heavy machinery, and automobile industries. Designed to work better in certain machining tasks, these tools have special finishes, advanced material formulas, and unique shapes.

Fundamental Design Features and Specifications

The shape of a taper mill directly affects how well it cuts and what kinds of jobs it can do. To meet different machining needs, these tools have different numbers of flutes, taper angles, and cutting sizes. The building of carbides makes them harder and more resistant to wear, and special finishes like titanium nitride make tools last a lot longer.

Material makeup is a very important factor in how well a tool works. When working with soft materials, high-speed steel options are very tough, while carbide options work better when working with hard materials. Which of these materials to use depends on the specific needs of Kuwait's business uses, such as the required hardness and production volume.

Customization Options for Kuwait's Industrial Landscape

The oil and gas industry in Kuwait needs specific tools that meet high standards of performance. Custom taper mills can be made with particular shapes, cutting angles, and surface processes to make them work best for drilling activities in a certain area. These changes make sure that the new equipment will work with the old equipment and increase the speed of operations.

During the tailoring process, machining factors like cutting speeds, feed rates, and depth of cut needs to be carefully thought through. Advanced finishing technologies make tools more durable in harsh settings, which means they last longer and don't need to be replaced as often. This ability to customize has a direct effect on the accuracy of the work, the speed of operations, and the life of tools in tough situations.

The Logistics of Shipping Custom Taper Mills from China to Kuwait

Shipping procedures that work well are essential for successful foreign procurement, especially when looking for precise tools for drilling jobs that need to be done quickly. Procurement managers can make smart decisions when they know about the different shipping choices and when they can be delivered.

Available Shipping Methods and Delivery Timeframes

There are many shipping choices available to meet the needs of people with varying levels of haste and budgets. Each way has its own benefits, which depend on the nature of the order and the transportation needs.

The fastest choice is air freight, which can bring custom taper mills in 5 to 7 days on average. This method works for replacing things quickly or meeting important project deadlines, but it costs more because it's faster. Express courier services offer the same speed as regular courier services, but they let you watch your packages better, making them perfect for both small and large orders.

Sea freight is a cheap way to send large goods, but it takes 14 to 21 days to get to Kuwait's ports. This method works out to be cost-effective for planned product replenishment or project needs on a big scale. Combined shipping methods can save money and meet the different arrival needs of different parts of an order.

Factors Influencing Delivery Timeline

Overall shipping plans are affected by production lead times in a big way, especially for tools that are highly customized. Standard setups usually take 7–10 days to make, but complicated changes can make this time take 15–20 days. Making sure that requirements are clear during the buying process helps keep production delays to a minimum.

The steps needed to clear customs in Kuwait can affect when the package is delivered in the end. This process goes more quickly if you prepare the right paperwork and know what the local import rules are. Suppliers with a lot of experience keep in touch with freight forwarders who are experts in Kuwaiti customs procedures. This cuts down on possible delays and makes sure that the delivery goes smoothly.

Key Factors Influencing the Performance and Maintenance of Custom Taper Mills

Understanding the important factors that affect cutting efficiency and upkeep needs is necessary to get the most out of a tool's performance and working lifespan. In tough drilling settings, these things have a direct effect on labor costs and levels of output.

Material Selection and Coating Technologies

The choice of tool material has a big effect on how well it works and what operations can be done with it. Carbide tools work best for high-speed tasks and cutting hard materials, while high-speed steel tools are very tough and can handle a wide range of cutting conditions. The choice between these materials depends on the needs and conditions of the application.

New covering technologies make taper mill last longer and cut better by a large amount. Titanium nitride coatings are very resistant to wear and cause less friction. Diamond-like carbon coatings, on the other hand, work better in tough situations. When compared to tools that aren't covered, these surface treatments can make them last twice or three times as long.

Operational Guidelines and Cutting Parameters

The best cutting speed depends a lot on the stiffness of the material, the shape of the tool, and the quality of the surface finish that you want. Conservative starting settings let optimization happen slowly while keeping the tool from breaking down too soon. Systematic parameter adjustment makes it possible to find the best settings for running certain apps.

Setting the right feed rate is important for balancing how quickly material is removed with how long the tool lasts. Higher feed rates make things more productive, but they may also wear out tools faster, especially when working with hard materials. By understanding this link, you can make smart choices that improve total operational efficiency instead of just cutting speed.

Maintenance Best Practices for Extended Tool Life

Inspections done on a regular basis find wear patterns and possible problems before they have a big effect on performance. Cutting edges show early signs of wear, chipping, or damage that need to be fixed when looked at visually. Systematic inspection routines make sure that the tool always works the same way during its operating time.

Corrosion and damage can be avoided during non-operational times by storing things in the right way. Clean, dry places with the right temperature control keep tools in good shape and make them last longer. High-value precision tools are better kept safe with protective boxes or special storage methods.

Procurement Strategies for Buying Custom Taper Mills Online from China

Strategic methods to purchase improve cost, quality, and service performance while lowering the risks that come with buying taper mills from other countries. These techniques help buying managers get the best results for their companies.

Price Comparison and Quality Assessment Methods

A full review of a supplier includes looking at more than just the original price quotes. Long-term worth is affected by tool life, performance, and support services that make up the total cost of ownership. This all-around method shows not only the cheapest sellers but also the ones that are the most cost-effective.

To judge quality, you have to look at how things are made, what materials are used, and test results from how well they work. Documentation from suppliers about quality gives information about what is expected in terms of regularity and dependability. By evaluating a sample tool, you can directly compare its performance to other tools before committing to bigger sales.

Negotiation Strategies for Bulk Orders

Buying in bulk can help you get better prices and terms by using economies of scale. When orders from different projects or teams are combined, the negotiating power goes up and the cost per unit goes down. Long-term partnership deals often come with extra perks, like getting first dibs on appointments and lower prices.

Especially for foreign orders, negotiating the terms of shipping can have a big effect on the total cost of the purchase. Knowing Incoterms and what they mean can help you make the best decisions about how to divide up costs and handle risks. Suppliers with a lot of experience can often give advice on the best ways to ship based on the details of the order and the delivery requirements.

Understanding Warranty and After-Sales Service Provisions

A full warranty guards against early failure and shows that the source trusts the quality of the product. Knowing about warranty terms, covering limits, and how to file a claim makes sure that tool purchases are properly protected. Making the paperwork needs clear makes it easier to handle the warranty when it's time.

Access to technical support is very helpful for getting the most out of tools and fixing problems that come up during operations. Support teams that are quick to respond can help solve problems quickly, cutting down on downtime and lost productivity. Support for multiple languages improves the speed and efficiency of conversation and problem-solving.

Conclusion

To get custom taper mills from China for Kuwait's drilling operations, shipping times, supplier selection factors, and strategic procurement approaches need to be carefully thought through. Delivery times usually run from one to five weeks, but they depend on how you want to customize it and which shipping way you choose. Reliable delivery is provided by quality providers with the right certifications, who also follow strict quality standards. Procurement managers can make choices that are more cost-effective and efficient for their drilling operations when they understand these factors.

FAQ

1. How long does it take to receive custom taper mills from China to Kuwait?

Shipping usually takes between 7 and 21 days, and special production can take an extra 10 to 15 days. Express air freight cuts the time it takes to ship to 5–7 days, while sea freight can take up to 21 days. For fully designed tools, the whole process usually takes three to five weeks from the time the order is placed.

2. What shipping options are available for taper mill delivery to Kuwait?

Air freight delivers the fastest, in 5 to 7 days; rush courier offers better tracking in the same time frames; and sea freight gives the most cost-effective options in 14 to 21 days. Combining shipping methods can get the best prices for all parts of an order while still meeting all of its arrival needs.

3. How do I verify supplier quality for custom taper mills?

Check for ISO 9001 and API 7-1 certifications, read case studies and customer testimonials, and look at the paperwork from the production site. Before committing to bigger orders, ask for sample tools to test their performance and make sure you understand the guarantee terms and can get expert help.

Partner with WELONG for Reliable Custom Taper Mill Solutions

WELONG is the taper mill source you can trust. They have been making products for over 20 years and have many quality standards, such as ISO 9001-2015 and API 7-1. Our personalized services provide well-thought-out answers that are perfectly suited to the tough digging conditions in Kuwait, guaranteeing top performance and longer equipment life. We offer full supply chain solutions that make your buying process easier by offering competitive prices, reliable delivery schedules, and quick technical help. Email our skilled staff at oiltools15@welongpost.com to talk about custom taper mill for sale and find out how our proven manufacturing skills can help your drilling operations run more smoothly and effectively.

References

1. Zhang, L., & Al-Rashid, M. (2023). International Supply Chain Management for Oil and Gas Equipment: How Trade Between China and Kuwait Works. Oil and Gas Equipment Manufacturing Journal, 45(3), 78–92.

2. Kuwait Industrial Development Authority. (2023). Strategic Guidelines for Equipment Procurement in Oil and Gas Operations. Annual Report of the Kuwait Ministry of Commerce, 156–189.

3. Wu, Chen, and Abdullah, K. (2022). An analysis of the performance of custom drilling tools in operations in the Middle East. 34(7), 234–251 in the International Journal of Oilfield Technology.

4. Maritime Logistics Research Institute. (2023). Improving the shipping route from China to the Gulf Cooperation Council countries. Asia-Pacific Trade Review, 28(4), 445–467.

5. Peterson, R., & Liu, H. (2023). Quality certification has an effect on the production of tools around the world. 19(2), 89–104 in Global Manufacturing Standards Quarterly.

6. Wang, T., & Al-Mahmoud, S. (2022). The best ways to buy specialized drilling equipment in Kuwait. The Middle East Industrial Review, 41(8), pp. 712–728.

Share your inquiry, get the quotation accordingly!

CHINA WELONG - 20+ years manufactuer in oilfield tools