Step-by-Step Guide: Drilling Jar Installation Basics

Selecting the Right Drilling Jar

Before installation, it's crucial to choose the appropriate drilling jar for your specific drilling operation. Consider factors such as well depth, formation characteristics, and expected loads. Hydraulic jars are often preferred for their precise control and versatility in both vertical and directional drilling.

Proper Placement in the Bottom Hole Assembly (BHA)

The position of the drilling jar within the BHA is critical for its effectiveness. Generally, it should be placed in the upper portion of the BHA, usually within the drill collars or heavy-weight drill pipe (HWDP). This placement ensures sufficient weight below the jar to keep it fully extended in vertical or low-angle wells.

Installation Steps

- Inspect the drilling jar for any visible damage or wear.

- Clean and lubricate all connections thoroughly.

- Align the jar with the drill string components above and below it.

- Make up the connections using proper torque specifications.

- Verify that the jar is oriented correctly for either up-jarring or down-jarring operations.

- Install accelerators or intensifiers if required for your specific application.

Pre-Installation Considerations

Before installing the drilling jar, consider the following:

- Ensure compatibility with other BHA components.

- Check that the jar's specifications match the well conditions and drilling program.

- Verify that the drilling crew is trained in proper jar operation and activation procedures.

Common Mistakes to Avoid During Jar Activation

Improper Timing of Activation

One of the most common mistakes in jar activation is poor timing. Activating the jar too early or too late can significantly reduce its effectiveness. It's essential to wait for the appropriate moment when sufficient energy has been stored in the drill string before triggering the jar.

Incorrect Force Application

Applying too much or too little force during activation can lead to suboptimal performance or even damage to the drilling jar. Operators must understand the specific force requirements for their jar type and adjust accordingly based on well conditions.

Neglecting Regular Maintenance

Failing to perform routine maintenance on the drilling jar can lead to unexpected failures during critical operations. Regular inspections, cleaning, and lubrication are essential for maintaining jar performance and reliability.

Overlooking Well Conditions

Ignoring changes in well conditions, such as temperature fluctuations or formation characteristics, can impact jar performance. Operators should continuously monitor and adjust their activation strategies based on current well conditions.

Optimizing Jar Performance: Timing and Force Considerations

Understanding Jar Mechanics

To optimize jar performance, it's crucial to understand the mechanics of how the jar operates. Hydraulic jars, for example, use a fluid metering system to delay the tripping action, allowing energy to build up in the drill string before release.

Calculating Optimal Overpull

Determining the right amount of overpull is critical for effective jar activation. This calculation should take into account factors such as:

- Drill string weight

- Well depth

- Formation characteristics

- Jar specifications

Monitoring and Adjusting Impact Force

The impact force delivered by the drilling jar can be adjusted by controlling the amount of overpull or set-down weight applied. Continuous monitoring and adjustment of these parameters can help optimize jar performance throughout the drilling operation.

Considering Well Trajectory

The well's trajectory plays a significant role in jar performance. In highly deviated or extended reach lateral wells, jars may need to run in compression rather than tension. Adjusting activation techniques based on well trajectory is essential for maximizing effectiveness.

Conclusion

Before beginning to drill, one must master the art of correctly installing and activating a drilling jar. By carefully following the instructions, avoiding typical errors, and optimising the use of timing and power, operators may greatly enhance their skill in unsticking jammed drill strings, resulting in little downtime. Always keep in mind that every well has its own set of problems, and that the only way to learn how to utilise drilling jars in different situations is to practise and adapt.

Call to Action

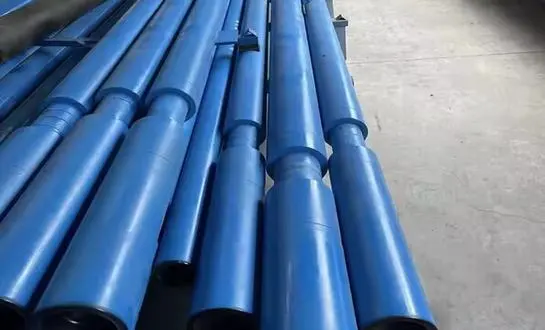

Are you in the market for dependable, high-performance drilling jars of the highest quality? Discover Welong, your one-stop shop. When it comes to drilling under difficult conditions, our completely hydraulic jars have shown to be dependable, accurate, and delivering great impact power. We are dedicated to providing you with the tools to optimise your drilling operations, drawing on our broad knowledge in oilfield goods and customised solutions.

Stop letting clogged pipes derail your progress. See the impact that superior craftsmanship and cutting-edge design can have by purchasing some drilling jars from Welong right now. If you need help deciding which drilling jar is best for your requirements, our team of specialists is here to help. Contact us now at oiltools15@welongpost.com to learn more about our products and how we can support your drilling success.