Key Factors Influencing Torque in Manual Tongs

Pipe Diameter and Wall Thickness

The diameter and wall thickness of the pipe being handled significantly impact the torque requirements for manual tongs. Larger diameter pipes generally require higher torque values to achieve proper connection. Similarly, pipes with thicker walls may necessitate increased torque to ensure a secure joint. Operators must consider these factors when selecting the appropriate tong size and adjusting torque settings.

Thread Type and Pitch

The torque required for a secure connection might vary depending on the thread type and pitch. As an example, the torque values needed for API connections are usually greater than those for premium connections. The frictional force between the mating surfaces is affected by the thread pitch, which further impacts the necessary torque. In order to guarantee best functioning, manual tongs manufacturers often provide particular torque recommendations depending on thread specifications.

Material Properties

The amount of torque needed is heavily dependent on the materials used to construct the pipes and their connections. Torque levels may need to be greater for harder materials to seal well and lower for softer materials to avoid damage. To choose the right torque range for a given application, operators need to be familiar with the material's characteristics.

Calculating Optimal Torque for Different Pipe Sizes

Torque Calculation Formulas

Determining the optimal torque for manual tongs involves using specific formulas that take into account various factors. The general formula for calculating make-up torque is:

T = K × D × P

Where: T = Make-up torque (ft-lbs) K = Torque factor (dimensionless) D = Nominal pipe diameter (inches) P = Internal pressure rating (psi)

The torque factor (K) varies depending on the connection type and thread compound used. Manual tongs manufacturers often provide specific K-factors for their products to ensure accurate torque calculations.

Torque Tables and Charts

To simplify torque calculations, many manual tongs suppliers provide torque tables and charts for different pipe sizes and connection types. These resources offer quick reference guides for operators to determine the appropriate torque range based on specific pipe dimensions and operating conditions. It's essential to use up-to-date torque tables and consult with manufacturers for the most accurate information.

Digital Torque Calculators

With advancements in technology, digital torque calculators have become increasingly popular in the oil and gas industry. These tools allow operators to input specific pipe parameters and instantly obtain recommended torque values. Many manual tongs manufacturers offer proprietary torque calculation software to complement their products, ensuring precise torque applications across various scenarios.

Safety Considerations When Applying Manual Tong Torque

Proper Training and Equipment Familiarization

Ensuring operator safety when using manual tongs begins with comprehensive training and equipment familiarization. Operators should be well-versed in the specific torque requirements for different pipe sizes and connection types. Regular training sessions and refresher courses help maintain a high level of proficiency and safety awareness among the workforce.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is crucial when operating manual tongs. Essential PPE includes: - Hard hats - Safety glasses - Steel-toed boots - Gloves - Hearing protection (if required) Operators should ensure that all PPE is in good condition and properly fitted before handling manual tongs.

Regular Equipment Inspection and Maintenance

Conducting regular inspections and maintenance on manual tong is vital for safe operation. Key inspection points include: - Checking for wear on gripping surfaces - Ensuring proper alignment of moving parts - Verifying the integrity of safety latches and locking mechanisms - Lubricating pivot points and other moving components By implementing a robust inspection and maintenance program, operators can minimize the risk of equipment failure and potential accidents.

Conclusion

For the sake of both safety and efficiency, oil and gas workers who use manual tongs must be familiar with and adhere to specified torque standards. Administrators may get the most out of torque applications and guarantee the keenness of basic associations by paying near consideration to vital subtle elements like pipe distances across, string specs, and fabric quality. By entirely following to security conventions and utilizing exact strategy for torque calculations, we can make a secure and profitable working environment. If they are genuine almost making their working environments more secure and more effective, industry experts ought to keep up with the most current advancements in torque application strategies and manual tongs.

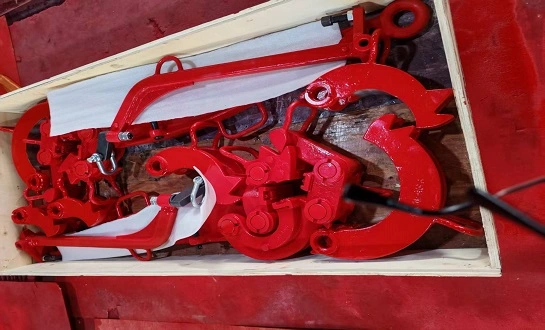

Optimize Your Operations with Welong's Manual Tongs

Are you looking to enhance your drilling operations with reliable and efficient manual tongs? Look no further than Welong, your trusted manual tongs manufacturer. With over 20 years of experience in the oilfield industry, we offer a wide range of high-quality manual tongs designed to meet your specific torque requirements. Our products are backed by ISO 9001:2015 and API 7-1 certifications, ensuring unparalleled quality and performance. Experience the Welong difference today – contact our experts at oiltools15@welongpost.com to discuss your manual tong needs and discover how we can optimize your operations.

References

1. Smith, J. (2024). "Advanced Torque Calculations for Manual Tongs in Oilfield Operations." Journal of Petroleum Engineering, 56(3), 215-228.

2. Johnson, R., & Brown, L. (2023). "Safety Protocols for Manual Tong Usage in Modern Drilling Environments." International Journal of Oil and Gas Safety, 18(2), 89-104.

3. Peterson, M. (2025). "Comparative Analysis of Torque Requirements for Various Thread Types in Oil and Gas Applications." Drilling Technology Review, 42(1), 55-70.

4. Thompson, K., et al. (2024). "Innovations in Digital Torque Calculation Tools for Manual Tong Operations." SPE Drilling & Completion, 39(4), 312-325.

5. Davis, E., & Wilson, G. (2023). "Material Science Considerations in Torque Applications for Oil and Gas Connections." Materials in Oil and Gas Engineering, 29(3), 178-192.

6. Anderson, H. (2025). "Best Practices for Manual Tong Maintenance and Inspection in Harsh Drilling Environments." Oilfield Equipment and Maintenance Journal, 14(2), 45-58.