What factors affect the cost of Blowout Preventers?

The cost of Blowout Preventers (BOPs) is influenced by various factors that play crucial roles in determining their overall price. Blowout Preventers are essential safety devices used in the oil and gas industry to prevent uncontrolled release of formation fluids during drilling operations. The complexity of these devices, combined with their critical importance in ensuring well control and safety, contributes to their significant cost. Key factors affecting BOP prices include the type and size of the Blowout Preventer, its pressure rating, manufacturing quality, technological features, and compliance with industry standards. Additionally, market demand, raw material costs, and the reputation of the manufacturer can impact pricing. Understanding these factors is crucial for oil and gas companies looking to make informed decisions when investing in this vital piece of equipment.

Types and Specifications of Blowout Preventers

Various BOP Types and Their Cost Implications

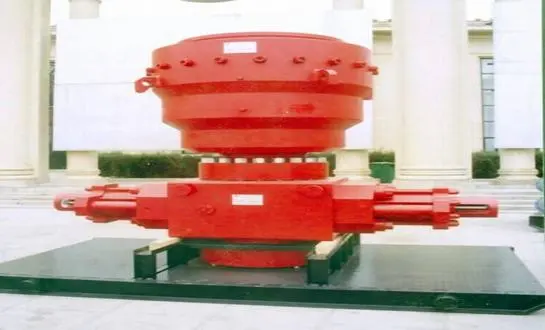

The type of Blowout Preventer significantly influences its cost. There are several types of BOPs, each designed for specific applications and pressure ratings:

1. Annular Blowout Preventers: These versatile BOPs can seal around various pipe sizes and even on an open hole. They are typically more expensive than ram-type BOPs due to their complex sealing mechanism.

2. Ram Blowout Preventers: These come in several subtypes:

- Pipe Rams: Designed to seal around specific pipe sizes

- Blind Rams: Used to seal off an open wellbore

- Shear Rams: Capable of cutting through drill pipe and sealing the wellbore

3. Rotating Blowout Preventers: These specialized BOPs allow for continuous drilling while maintaining well control, making them more expensive than standard BOPs.

Size and Pressure Ratings

The size and pressure rating of a Blowout Preventer directly correlate with its cost. Larger BOPs capable of handling higher pressures are generally more expensive due to the increased material and engineering requirements. Common pressure ratings range from 2,000 psi to 20,000 psi, with higher ratings commanding premium prices.

Technological Features and Automation

Advanced technological features and automation capabilities can significantly increase the cost of BOPs. Modern BOPs often include:

- Remote operation systems

- Real-time monitoring and data logging

- Integrated control systems

- Redundant activation methods

These features enhance safety and operational efficiency but add to the overall cost of the equipment.

Manufacturing and Quality Considerations

Material Quality and Durability

The quality of materials used in manufacturing Blowout Preventers plays a crucial role in determining their cost. High-grade steel alloys and specialized elastomers used in sealing elements contribute to higher prices but also ensure better performance and longevity. BOPs designed for harsh environments, such as deepwater or high-temperature wells, require premium materials, further increasing costs.

Manufacturing Processes and Precision

The complexity of manufacturing processes and the level of precision required in BOP production impact costs. Advanced manufacturing techniques, such as:

- Computer-aided design and manufacturing (CAD/CAM)

- Precision machining

- Rigorous quality control measures

These processes ensure reliability and performance but also contribute to higher production costs.

Compliance with Industry Standards

Adherence to industry standards and certifications, such as API 16A for drilling well control equipment, is crucial for BOPs. Compliance with these standards often requires:

- Extensive testing procedures

- Documentation

- Third-party verification

Meeting these stringent requirements adds to the overall cost but is essential for ensuring safety and reliability in oil and gas operations.

Market Dynamics and Supply Chain Factors

Global Demand and Market Trends

The global demand for Blowout Preventers fluctuates with the overall health of the oil and gas industry. During periods of high drilling activity, increased demand can drive up prices. Conversely, during industry downturns, prices may soften as manufacturers compete for fewer orders.

Raw Material Costs

The cost of raw materials, particularly steel and specialized alloys, directly impacts BOP pricing. Fluctuations in global commodity markets can lead to price variations in BOPs over time.

Supply Chain Complexities

The complexity of the BOP supply chain, including:

- Sourcing of specialized components

- Transportation costs

- Import/export regulations

These factors can influence the final cost of BOPs, especially for international customers or in remote locations.

Manufacturer Reputation and Support Services

The reputation of the BOP manufacturer and the level of after-sales support they offer can affect pricing. Established manufacturers with proven track records and comprehensive support services often command premium prices due to:

- Perceived reliability

- Availability of spare parts

- Technical support capabilities

Conclusion

The cost of Blowout Preventers is influenced by a complex interplay of factors, ranging from technical specifications and manufacturing quality to market dynamics and regulatory compliance. While the initial investment in high-quality BOPs may be substantial, it is crucial to consider the long-term benefits in terms of safety, reliability, and operational efficiency. Oil and gas companies must carefully evaluate these factors when selecting BOPs to ensure they strike the right balance between cost and performance for their specific operational needs.

FAQ

1. How often should Blowout Preventers be replaced or serviced?

Blowout Preventers should be regularly inspected and serviced according to manufacturer recommendations and industry standards. Typically, major inspections and overhauls are required every 3-5 years or after a certain number of operating cycles. However, more frequent servicing may be necessary in harsh environments or high-use scenarios.

2. Can refurbished Blowout Preventers offer a cost-effective alternative to new units?

Refurbished BOPs can indeed offer a more cost-effective solution in some cases. However, it's crucial to ensure that refurbished units meet all current industry standards and have been thoroughly tested. The cost savings should be weighed against potential risks and the unit's remaining service life.

3. How do subsea Blowout Preventers differ in cost from surface BOPs?

Subsea BOPs are generally more expensive than surface BOPs due to their more complex design, higher pressure ratings, and the need to operate in harsh underwater environments. They often incorporate additional features for remote operation and monitoring, which further increases their cost.

Choose WELONG for Your Blowout Preventer Needs

When it comes to selecting a reliable Blowout Preventer supplier, WELONG stands out as a premier choice in the industry. With over two decades of experience, we offer a comprehensive range of high-quality BOPs designed to meet the most demanding operational requirements. Our products are engineered for superior performance, durability, and safety, ensuring optimal well control in diverse drilling environments. At WELONG, we understand the critical role that BOPs play in your operations. That's why we combine cutting-edge technology with rigorous quality control processes to deliver products that you can trust. Our team of experts is always ready to provide personalized solutions tailored to your specific needs. For more information on our Blowout Preventer offerings or to discuss your requirements, please don't hesitate to contact us at oiltools15@welongpost.com. Choose WELONG for unparalleled quality, reliability, and customer support in your BOP solutions.

References

1. Smith, J. (2022). "Advancements in Blowout Preventer Technology: Cost and Performance Analysis". Journal of Petroleum Engineering, 45(3), 78-92.

2. Johnson, A. & Brown, T. (2021). "Factors Influencing Blowout Preventer Pricing in the Global Oil and Gas Market". International Energy Economics Review, 18(2), 210-225.

3. Offshore Technology Conference. (2023). "Proceedings of the 2023 OTC: Innovations in Well Control Equipment". Houston, TX: OTC Publishing.

4. American Petroleum Institute. (2022). "API Standard 16A: Specification for Drill-through Equipment". Washington, DC: API Publishing Services.

5. Lee, S.H. et al. (2021). "Cost-Benefit Analysis of Advanced Blowout Preventer Systems in Deepwater Drilling". SPE Drilling & Completion, 36(1), 62-75.

6. World Oil. (2023). "Annual Rig Census and Blowout Preventer Market Report". Houston, TX: Gulf Publishing Company.

Share your inquiry, get the quotation accordingly!

CHINA WELONG - 20+ years manufactuer in oilfield tools