Comparing Blade vs. Roller Cone Openers

Understanding the differences between blade and roller cone hole openers is essential for making an informed decision when drilling in clay or soft formations. Both types have their strengths and weaknesses, which can significantly impact drilling efficiency and wellbore quality.

Blade Hole Openers

Blade hole openers are particularly well-suited for clay and soft formations due to several key advantages:

- Shearing Action: The blades provide a more efficient cutting mechanism in softer materials, removing formation material with less energy input.

- Reduced Vibration: The continuous cutting surface of blades results in smoother operation, minimizing vibration that can destabilize the wellbore.

- Improved Hydraulics: Blade designs often allow for better fluid flow, enhancing cuttings removal and reducing the risk of bit balling in sticky clay formations.

- Wellbore Stability: The cutting action of blades tends to produce a more stable wellbore in soft formations, reducing the risk of collapse or washouts.

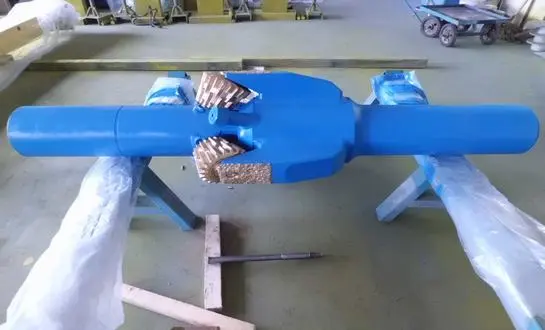

Roller Cone Hole Openers

While roller cone openers have their place in drilling operations, they may face challenges in clay and soft formations:

- Crushing Action: Roller cones work by crushing the formation, which can be less efficient in softer materials and may lead to compaction rather than removal.

- Increased Vibration: The rotating cones can generate more vibration, potentially leading to wellbore instability in soft formations.

- Cuttings Removal: In sticky clay formations, roller cones may struggle with efficient cuttings removal, increasing the risk of bit balling and reduced rate of penetration (ROP).

- Wear and Tear: Soft, abrasive formations can cause accelerated wear on roller cone bearings, potentially leading to premature failure.

While roller cone openers have their advantages in harder formations, the characteristics of blade hole openers make them generally more suitable for clay and soft formation drilling.

Key Factors: Formation Type and Wellbore Stability

When selecting a hole opener for clay or soft formations, it's crucial to consider the specific formation characteristics and their impact on wellbore stability. These factors play a significant role in determining the most effective tool for the job.

Formation Characteristics

Clay and soft formations can vary widely in their properties, affecting how different hole openers perform:

- Clay Plasticity: Highly plastic clays can be prone to swelling and sticking, making efficient cuttings removal critical.

- Formation Hardness: Even within the category of "soft" formations, there can be significant variations in hardness that influence opener selection.

- Abrasiveness: Some soft formations can be surprisingly abrasive, impacting the wear rate of opener components.

- Porosity and Permeability: These properties affect fluid interaction with the formation, influencing stability and drilling fluid requirements.

Wellbore Stability Considerations

Maintaining wellbore stability is paramount in clay and soft formations, and the choice of hole opener can significantly impact this:

- Shear Strength: Softer formations with low shear strength are more prone to collapse, requiring a hole opener that minimizes formation disturbance.

- Fluid Sensitivity: Many clays are sensitive to drilling fluids, potentially leading to swelling or dispersion. The hole opener must work in concert with the drilling fluid to maintain stability.

- Stress State: Understanding the in-situ stress state helps predict potential wellbore instability issues and informs opener selection.

- Overburden Pressure: In deeper formations, higher overburden pressure can exacerbate stability issues, necessitating careful opener selection and operation.

By carefully considering these formation and stability factors, drillers can select a hole opener that not only efficiently enlarges the wellbore but also contributes to overall wellbore stability and drilling success in clay and soft formations.

Selecting the Right Opener

Choosing the optimal hole opener for clay or soft formations involves a comprehensive evaluation of various factors to ensure efficient drilling and wellbore quality. Here's a guide to help you make an informed decision:

Evaluating Hole Opener Design Features

When selecting a hole opener for soft formations, consider these design elements:

- Blade Configuration: Look for designs with optimized blade angles and spacing for efficient material removal in soft formations.

- Cutter Technology: Advanced PDC (Polycrystalline Diamond Compact) cutters or specialized soft formation inserts can improve cutting efficiency.

- Hydraulic Optimization: Choose openers with features that enhance fluid flow and cuttings evacuation, crucial in sticky clay environments.

- Gauge Protection: Ensure adequate gauge protection to maintain hole size in soft, abrasive formations.

Operational Considerations

Beyond design, operational factors play a crucial role in hole opener performance:

- Rotary Speed: Optimize RPM for the specific formation to balance ROP with wellbore stability.

- Weight on Bit (WOB): Adjust WOB to achieve efficient cutting without overloading the opener in soft formations.

- Hydraulics Management: Fine-tune flow rates and nozzle configurations to optimize hole cleaning and prevent bit balling.

- Drilling Fluid Properties: Select and maintain drilling fluid properties that complement the hole opener's performance in clay formations.

Formation-Specific Customization

Tailoring your hole opener selection to specific formation characteristics can significantly enhance performance:

- Custom Blade Profiles: Some manufacturers offer customized blade profiles optimized for particular clay or soft formation types.

- Hybrid Designs: In transitional formations, hybrid openers combining blade and roller cone elements might provide the best performance.

- Anti-Balling Features: Look for designs with specific anti-balling features for highly sticky clay formations.

- Stabilization Options: Consider integrated stabilization features that can enhance wellbore stability in soft formations.

By carefully evaluating these aspects and consulting with experienced professionals, you can select a hole opener that maximizes efficiency and wellbore quality in clay and soft formations. Remember that the ideal choice may vary depending on the specific challenges of your drilling project.

Conclusion

In conclusion, when drilling in clay or soft formations, blade-style hole openers generally offer superior performance due to their efficient cutting action, reduced vibration, and better hydraulics. However, the optimal choice depends on a thorough analysis of formation characteristics, wellbore stability considerations, and operational parameters. By carefully evaluating these factors and selecting a hole opener with appropriate design features and customization options, you can significantly enhance your drilling efficiency and wellbore quality in challenging soft formation environments. For expert guidance on selecting the right hole opener for your specific drilling needs, don't hesitate to reach out to industry professionals. To learn more about high-quality hole openers and other oilfield products tailored for various formation types, contact us at oiltools15@welongpost.com.