To meet world safety and operational standards for drilling, choke manifold systems must be compliant with API 16C. To keep well kicks in check, oil and gas pumping pressure control technology uses the choke manifold. This detailed guide helps purchasing managers, engineers, and drilling contractors pick and keep up with API 16C-compliant systems by going over technical standards, engineering factors to think about, and useful ways to put them into action. By understanding these standards, decision-makers can make operations more reliable, avoid costly breakdowns, and make sure that equipment meets all laws throughout its lifecycle.

Understanding API 16C Choke Manifold Standards

API 16C is the industry standard for drilling pressure control equipment design, manufacturing, and operation. This standard covers material criteria, pressure testing, and safety measures for reliable well control.

Why Does API 16C Matter for Choke Manifolds?

API 16C mandates choke and kill equipment specifications for drilling operations, protecting humans and the environment. The standard specifies pressure ratings, material composition, and functional testing methodologies that affect manifold performance. API 16C compliance assures equipment can resist harsh operational circumstances and retain precise pressure management for balanced drilling.

Essential Choke Manifold Functions In API 16C

API 16C requires choke manifolds to regulate pressure and remain structurally sound under various operational loads. Manifolds must have redundant choke valves, pressure monitoring equipment, and emergency shutdown procedures. These systems must resist corrosion and remain leak-tight during long periods of operation within defined temperature ranges.

Key Parts Impacted by API 16C

API 16C compliance directly influences the design and selection of critical manifold components, including choke valves, gate valves, line pipes, fittings, and pressure gauges. The specification requires materials to tolerate hydrogen sulfide and corrosive drilling fluids while retaining operational reliability. Valve specs must fulfill strict sealing standards and perform consistently under drilling cyclic loading situations.

Expert Engineering Checklists for API 16C Compliance

Implementing systematic engineering checklists throughout the equipment lifecycle ensures consistent API 16C compliance while optimizing operational performance and safety outcomes. These comprehensive verification protocols address design validation, manufacturing quality control, installation procedures, and ongoing maintenance requirements.

Design Principles Checklist

Design validation begins with material selection verification ensuring components meet API 16C corrosion resistance and mechanical strength requirements. Engineers must confirm pressure rating calculations align with maximum anticipated well pressures while incorporating appropriate safety factors. The following critical design elements require verification:

- Material compliance with NACE MR-0175 requirements for sour service applications

- Pressure containment design meeting API 6A specifications

- Valve arrangement providing redundant flow paths and emergency isolation capabilities

- Integration compatibility with existing BOP systems and control networks

These design considerations directly impact system reliability and operational safety, making thorough verification essential during the engineering phase.

Manufacturing and Quality Assurance Checklist

To make sure that manufacturing standards are met, strict quality control methods must be used to make sure that every part meets API 16C requirements before it is put together. Important manufacturing checkpoints include making sure the welding process is correct, following the rules for non-destructive testing, and making sure the pressure testing is correct. To show that they are following API standards, quality assurance programs must keep records of how materials are traced, how they are made, and the results of the final review.

Checklist for Installation and Commissioning

The right way to install manifold systems makes sure they work the way they're supposed to and stay in compliance with API 16C during practical deployment. Installation teams have to check the orientation of the parts, the link torque requirements, and how well the system works with the well control equipment that is already in place. As part of the commissioning process, pressure tests, working checks of all valves and control systems, and writing down system performance parameters are all things that need to be done.

Checklist for Operation and Maintenance

For ongoing compliance, you need to have systematic maintenance routines that include checking parts, keeping an eye on how they're working, and setting up replacement schedules before they break. Regular pressure tests, checking the function of valves, and writing down any changes or repairs to the system that might affect its API 16C compliance status are all part of operational routines.

Procurement Considerations for API 16C Compliant Choke Manifolds

Effective procurement strategies balance compliance requirements with operational needs, cost considerations, and delivery timelines essential for successful project execution. Understanding supplier capabilities and product specifications enables informed decision-making while ensuring long-term operational success.

Supplier Selection and Verification

Quality systems, certification maintenance, and technical competence ensure API 16C compliance from reliable providers. Facility audits, quality system evaluations, and reference checks should verify project delivery. Suppliers must provide extensive product compliance documentation and commit to standard updates and technical upgrades.

Custom vs. Standard Choke Manifolds

Custom solutions meet operational needs that regular manifold designs cannot, while standard configurations comply and deliver faster. Custom engineering optimizes for unique operational conditions of choke manifold but requires additional API 16C approval. Both approaches can yield outstanding outcomes when managed by qualified vendors with engineering skills.

Pricing, Warranty, and Support

A complete cost analysis should cover equipment, installation, maintenance, and long-term operational costs. Warranty terms must cover compliance maintenance and technical support throughout equipment lifecycle. After-sales service affects compliance and operational reliability, making supplier support a key consideration.

Negotiating bulk purchases and contracts

Volume purchase can save money and ensure product quality and compliance across installations. Contracts should cover delivery, quality, and technical support while allowing project-specific changes. Long-term supplier partnerships offer qualified buyers better assistance and pricing.

Embedding Company Expertise and Product Solutions

WELONG has over two decades of oilfield equipment manufacturing experience, providing API 16C compliant solutions that exceed industry standards and fulfill different global operational requirements.

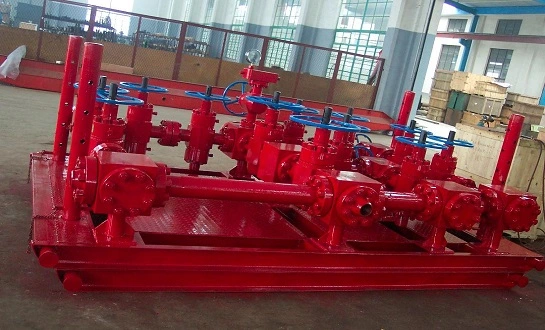

Our entire manifold line meets API Spec 6A, API Spec 16C, and NACE MR-0175 standards with superior engineering. These systems provide regular freight alternatives while meeting industry standards due to their reduced weight and footprint. Manual and hydraulic actuators, universal function LCP systems, and fixed and lifting base installation are available. Modern drilling requires remote operation via hydraulically actuated components.

Engineering help from WELONG includes design advice, installation guidance, and ongoing maintenance to ensure project success and compliance. Our expert production team completes manufacture and delivers to global client warehouses on schedule. We offer sea, air, and train freight with FOB, CIF, DDP, and DDU conditions. Our quality control method comprises in-process and final inspections, as well as third-party verification through SGS and DNV collaborations. This comprehensive strategy ensures product dependability and compliance throughout manufacturing and provides customers with detailed operational documentation.

Conclusion

API 16C compliance is essential for safe and reliable choke manifold operations worldwide. These standards enable equipment selection, operational safety, and regulatory compliance. WELONG's full manifold design, manufacturing, and support services fulfill the most demanding operational requirements while preserving API 16C compliance throughout the equipment lifecycle.

Frequently Asked Questions

Q1: What makes a choke valve work with API 16C?

A: In order to be API 16C compliant, manifolds must meet certain design standards. These include pressure ratings, material requirements, safety system requirements, and testing methods. Systems that are compliant must be able to control pressure reliably, have two sets of safety features, and be made of materials that meet NACE standards for corrosive environments.

Q2: In line with API 16C, how often should repair be done on choke manifolds?

A: API 16C suggests regular repair and inspection schedules that are based on how busy the business is and the weather. Daily operational checks, weekly pressure tests, monthly component inspections, and a yearly full system verification are all common maintenance intervals. Depending on how often they are used, critical parts may need more frequent care.

Q3: Is it possible to make choke valves that already exist meet API 16C standards?

A: The ability to retrofit relies on the condition of the existing equipment and the limits of the design. Compliance can be reached with some changes, like better pressure tracking or better valve systems, but structural problems may mean that the whole thing needs to be replaced. The most cost-effective way to install certain things is determined by a professional assessment.

Partner with WELONG for Superior Choke Manifold Solutions

WELONG stands ready to support your pressure control equipment needs with industry-leading expertise and proven API 16C compliant solutions. As an established choke manifold manufacturer with over 20 years of experience, we provide comprehensive support from initial design through long-term maintenance. Our certified quality systems and global supply chain capabilities ensure reliable delivery while maintaining the highest compliance standards. Whether you require standard configurations or custom-engineered solutions, our technical team provides expert consultation tailored to your specific operational requirements. Contact us at oiltools15@welongpost.com to discuss your next project and experience the WELONG advantage in pressure control technology.

References

- American Petroleum Institute. "API Specification 16C: Choke and Kill Equipment." Fourth Edition. Washington, DC: API Publishing Services, 2019.

- National Association of Corrosion Engineers. "NACE MR0175/ISO 15156: Petroleum and Natural Gas Industries - Materials for Use in H2S-Containing Environments." Houston, TX: NACE International, 2020.

- International Association of Drilling Contractors. "Well Control Equipment Maintenance and Testing Guidelines." Houston, TX: IADC Technical Publications, 2021.

- Society of Petroleum Engineers. "Pressure Control Equipment Standards and Best Practices for Drilling Operations." Richardson, TX: SPE Technical Publications, 2020.

- American Petroleum Institute. "API Specification 6A: Wellhead and Tree Equipment." Twenty-first Edition. Washington, DC: API Publishing Services, 2018.

- Offshore Technology Research Center. "Advanced Pressure Control Systems in Deepwater Drilling Operations." College Station, TX: Texas A&M University Press, 2019.