Where Kuwait Oil Companies Buy Breakout Units from China?

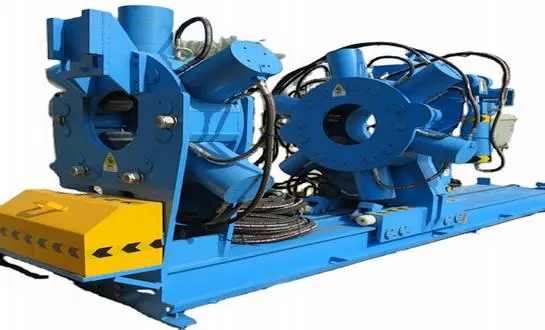

China is the world's leading oilfield equipment manufacturer, and breakout units are in high demand. Over the last two decades, the country's manufacturing industry has grown from a low-cost production base to a complex industrial ecosystem that produces high-quality drilling equipment that satisfies worldwide standards. Demand for dependable breakout units rises as drilling operations become more sophisticated and safety standards increase. Modern drilling operations depend on these hydraulic-powered devices to efficiently assemble and disassemble threaded connections while maintaining operator safety and accuracy. Kuwaiti oil firms buy breakout units from China Welong, oilfield equipment providers, and trusted B2B platforms. The vast oil infrastructure of Kuwait requires these hydraulic-powered multipurpose devices for casing and tubing. Chinese manufacturers have gained market share owing to their cheap pricing, excellent technological integration, and complete after-sales assistance that meets Middle Eastern drilling operations' demanding needs.

China's Manufacturing Excellence in Breakout Unit Production

Advanced Production Capabilities

Decendents of experience and significant production technology investments assist China's breakout unit manufacturing industry. To assure quality, modern facilities include computer-controlled machining centers, automated welding, and precise testing equipment. Manufacturing often uses hydraulic systems for pressure control, transmission components for durability, and automation features for operational efficiency. Chinese factories can produce breakout units of different sizes and characteristics. These factories follow strong quality control standards from raw material selection to product testing. Advanced metallurgy is used to make oilfield components resistant to harsh circumstances.

Economical Manufacturing Solutions

The competitive edge of Chinese breakout unit makers goes beyond price. While cost control is vital, the value offer includes efficient manufacturing, economies of scale, and streamlined supply chain management. Manufacturers use bulk raw material purchases, efficient manufacturing processes, and smart geographic placement to produce cost-effective, high-quality solutions. Automation and process optimization boost production efficiency, allowing enterprises to compete on price while retaining profit margins. This technique helps foreign customers seeking quality equipment at affordable prices, especially for large-scale drilling operations where equipment acquisition is a major capital outlay.

Technological Innovation Integration

Major Chinese manufacturers spend in R&D to improve breakout unit performance and functionality. Contemporary machines include hydraulic control systems, torque monitoring computers, and safety measures that transcend conventional equipment. These technical advances meet industrial demands for accuracy, safety, and efficiency. Innovation allows manufacturers to customize conventional designs for operational needs. This versatility benefits multinational customers working in various geological conditions or using unique drilling methods that need customized equipment.

Proven Methods for Identifying Reliable Manufacturers

Comprehensive Due Diligence Research

A thorough manufacturer study starts with firm credentials, manufacturing history, and market repute. Reliable suppliers have long operating history, oilfield equipment manufacturing experience, and worldwide customer ties. Research should evaluate financial stability, manufacturing capacity, and quality management systems. Professional networks in the oil and gas sector reveal manufacturer performance and dependability. Industry groups, trade journals, and peer recommendations provide reliable supplier and service quality information. This knowledge is crucial when selecting partners among the many manufacturers.

Production Facility Assessment

Direct plant inspections or complete virtual audits reveal production and quality control skills. Modern manufacturing facilities should have enough equipment, coordinated workflow, and skilled staff. Actual manufacturing procedures indicate quality and operational efficiency. Evaluation of quality control infrastructure comprises testing equipment, calibration methods, and documentation systems. Quality assurance processes include incoming material inspection, in-process monitoring, and final product certification by reliable manufacturers. International standards and consumer needs should guide these systems.

Customer Reference Check

Established manufacturers generously give customer references and case studies of project completion and continuing connections. Reference verification entails talking to past customers about product performance, delivery dependability, and after-sales service. This feedback tells the truth about manufacturer capabilities and service. Manufacturer dependability and service excellence are shown by long-term customers. Companies with multi-year international customer agreements usually perform well and adapt to changing needs. Diverse references from diverse geographic markets and application kinds demonstrate manufacturer adaptability and skill.

Evaluation of Technical Capability

Manufacturing partners should have design, manufacturing, and application support knowledge. Engineering design optimization, material selection, and application customisation are technical skills. Evaluation should evaluate the manufacturer's technical support throughout the product lifespan. Documentation quality shows technical expertise and professionalism. Comprehensive technical specifications, precise drawings, and complete testing results reflect methodical product development and quality assurance. Producers should offer explicit proof of product performance and specification compliance.

Assessing financial stability

Supplier financial stability guarantees breakout unit lifetime supply and support. Financial assessment includes credit rating, company registration, and operational scale checks. Stable manufacturers have steady growth, sufficient cash, and diverse client bases. Payment terms and price reveal financial practices and corporate viability. Competitive pricing and reasonable payment conditions reflect good company operations. Extremely aggressive pricing without value explanation may indicate unsustainable company practices or quality concessions.

OEM and ODM Partnership Considerations

Customization Capabilities Assessment

Customizable and adaptable manufacturers are needed for OEM relationships. Evaluation should evaluate design change, tooling development, and production adaption adaptability. Manufacturers should have expertise with specific needs and maintain quality throughout customisation of breakout units. Successful OEM agreements need technical cooperation. Manufacturers should provide technical assistance with design optimization, material selection, and manufacturing process advice. Collaborative methods typically outperform basic specification fulfillment.

IP Protection

OEM alliances demand strong IP protection and confidentiality agreements. Manufacturers should show processes for securing client designs, specifications, and confidential information. Legal frameworks should cover IP ownership, use rights, and protection throughout the collaboration. Clear documentation and agreements reduce disagreements and ensure rights and duties are understood. Design ownership, modification rights, market exclusivity, and quality standard maintenance should be included in comprehensive agreements.

Scalability and production capacity

OEM partners must show sufficient manufacturing capacity for expected volumes and demand flexibility. Current use, growth capacity, and resource allocation flexibility should be assessed. Manufacturers should provide realistic production and delivery timeframes based on confirmed capability. Scalability becomes vital as company partnerships and volumes grow. Partners must increase production effectively while maintaining quality and delivery dependability. Expansion planning and investment capabilities evaluation promote partnership longevity.

Quality Control and Factory Audit Implementation

Comprehensive Audit Protocols

Systematic factory audits encompass production capability assessment, quality system evaluation, and operational procedure verification. Audit protocols should address manufacturing equipment adequacy, personnel qualifications, and quality control system effectiveness. Comprehensive audits provide essential insights into manufacturer capabilities and operational standards.

Documentation review forms a critical component of effective audits, examining quality manuals, procedure documentation, and certification records. Proper documentation indicates systematic approaches to quality management and provides evidence of compliance with specified standards and requirements.

In-Process Quality Monitoring

Ongoing quality monitoring throughout production provides early identification of potential issues and ensures consistent output quality. Monitoring systems should encompass material inspection, in-process testing, and final product validation. Regular monitoring prevents quality issues from propagating through production runs and ensures specification compliance.

Communication protocols establish clear procedures for quality issue reporting, corrective action implementation, and resolution verification. Effective communication ensures rapid response to quality concerns and prevents minor issues from becoming major problems affecting delivery schedules or product performance.

Third-Party Inspection Integration

Independent inspection services provide unbiased quality verification and compliance confirmation according to specified requirements. Third-party inspectors offer expertise in quality assessment and certification that may exceed internal capabilities. Integration of inspection services into procurement processes adds quality assurance and documentation value.

Inspection timing and scope should align with production schedules and quality requirements. Pre-shipment inspection prevents defective products from entering supply chains, while in-process inspection identifies issues early in production cycles. Comprehensive inspection programs provide maximum quality assurance value.

Conclusion

To find the best breakout unit maker in China, you need to carefully look at their technical skills, quality standards, and service promises. Doing your research, evaluating the place in detail, and carefully checking certificates and references are all important for success. Clear communication, equal knowledge of needs, and a shared dedication to quality and service greatness are the building blocks of the most trusted relationships. China's industrial sector is still changing as it moves toward higher quality standards, better customer service, and the merging of new technologies. Leading makers show dedication to global norms, caring for the environment, and digital progress, which helps partnerships succeed in the long run. When choosing a strategic seller, these things should be taken into account to make sure that you get solid tools and help throughout the entire working lifetime.

Frequently Asked Questions

1. What kinds of licenses should I look for in a company that makes breakout units?

ISO 9001:2015 for quality management systems and API 7-1 for drilling tools requirements are two important certifications. Some other useful approvals are the CE mark, which shows that the product meets safety standards, and third-party validation from groups like SGS or DNV. Environmental standards like ISO 14001 show that you care about the long term.

2. How can I find out how much a company can make?

To check the production capacity, you need to visit the plant or do a full virtual assessment. You also need to look at lists and specs of equipment and current production plans. Ask for examples from customers who have similar number needs and look at how well they have been delivered in the past. Take yearly changes and the distribution of capacity among product lines into account.

3. What causes Chinese makers' breakout unit prices to change?

Price factors include the cost of raw materials, the difficulty of production, the number of orders, the need for tailoring, and the time it takes to send the goods. Costs are also affected by competitors in the market, the extra costs of the producer, and the profit margin. Total cost is affected by payment terms, shipping plans, and the services provided after the sale.

Partner with WELONG for Premium Breakout Unit Solutions

WELONG stands as your trusted breakout unit manufacturer, delivering exceptional hydraulic-powered equipment that meets the demanding requirements of modern drilling operations. With over two decades of specialized experience and certifications including ISO 9001:2015 and API 7-1, we provide reliable solutions backed by comprehensive quality assurance and global service support. Our advanced manufacturing capabilities, competitive pricing, and customization expertise make us the preferred choice for international drilling contractors and equipment manufacturers seeking dependable breakout unit suppliers.

Contact our technical team at oiltools15@welongpost.com to discuss your specific requirements and discover how our innovative breakout units can optimize your drilling operations while ensuring safety and efficiency standards.

References

1. International Association of Drilling Contractors. "Global Drilling Equipment Market Analysis and Manufacturing Trends." Annual Industry Report, 2024.

2. American Petroleum Institute. "API Specification 7-1: Specification for Rotary Drill Stem Elements." Forty-sixth Edition, 2023.

3. China Petroleum Equipment Manufacturing Association. "Export Statistics and Quality Standards for Chinese Oilfield Equipment." Industry Analysis Report, 2024.

4. Middle East Oil and Gas Technology Conference. "Procurement Strategies and Supplier Selection Criteria for Drilling Equipment." Conference Proceedings, 2024.

5. International Organization for Standardization. "ISO 9001:2015 Quality Management Systems Requirements and Implementation Guidelines." Technical Documentation, 2023.

6. Kuwait National Petroleum Company. "Equipment Procurement and Quality Assurance Standards for Upstream Operations." Internal Policy Document, 2024.

Share your inquiry, get the quotation accordingly!

CHINA WELONG - 20+ years manufactuer in oilfield tools